From Railcar

Services / Transload /

From Railcar

Welcome Flexibility, Lightening the railcar

Railcars revolutionized the transportation of many dry bulk commodities. Throughout the manufacturing industries, they are used extensively for the distribution, storage and transfer of bulk solid materials.

RB’s main goal is to understand the logistic needs of our customers and provide solutions that improve and secure the supply chain process. We focus on creating flexibility around railcar logistics. Our transloading solutions enable our customers the possibility to transfer their materials into more cost-efficient transport units and optimize the usage of the covered hopper cars.

In addition to the charges of freight from origin to destination, railroads charge for accessorial services such as demurrage, furtherance and storage. These chargeable services were one of the forms introduced in the business to increase the efficiency of railcars allocation. Equipment sitting idle while waiting to load and unload incurs high opportunity cost savings.

Supply chain challenges are a driving force in the development of new logistical strategies to pursue the goals of cost reduction and customer service improvement.

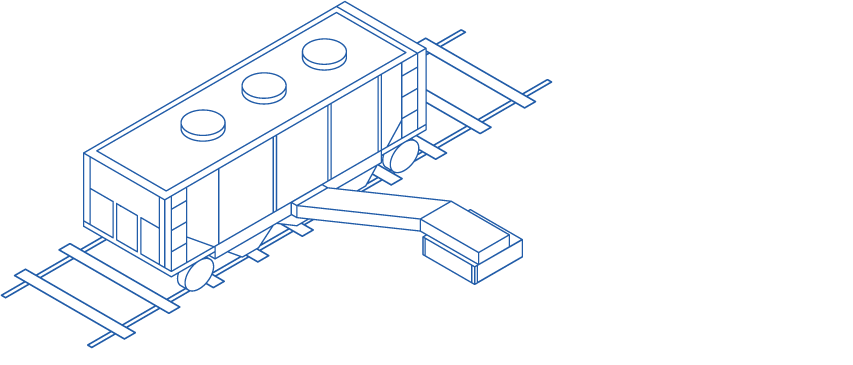

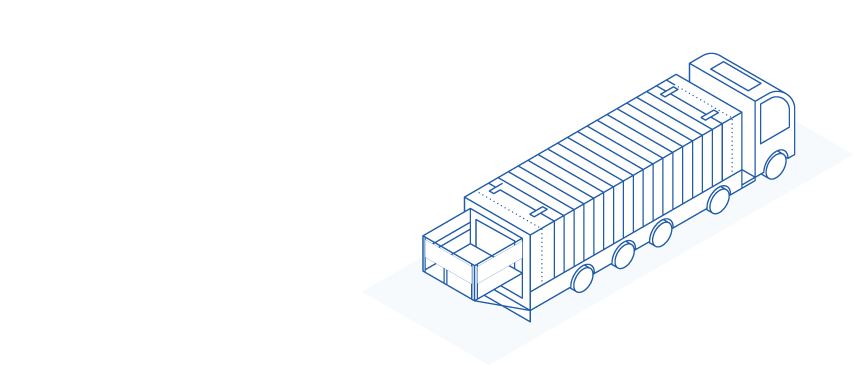

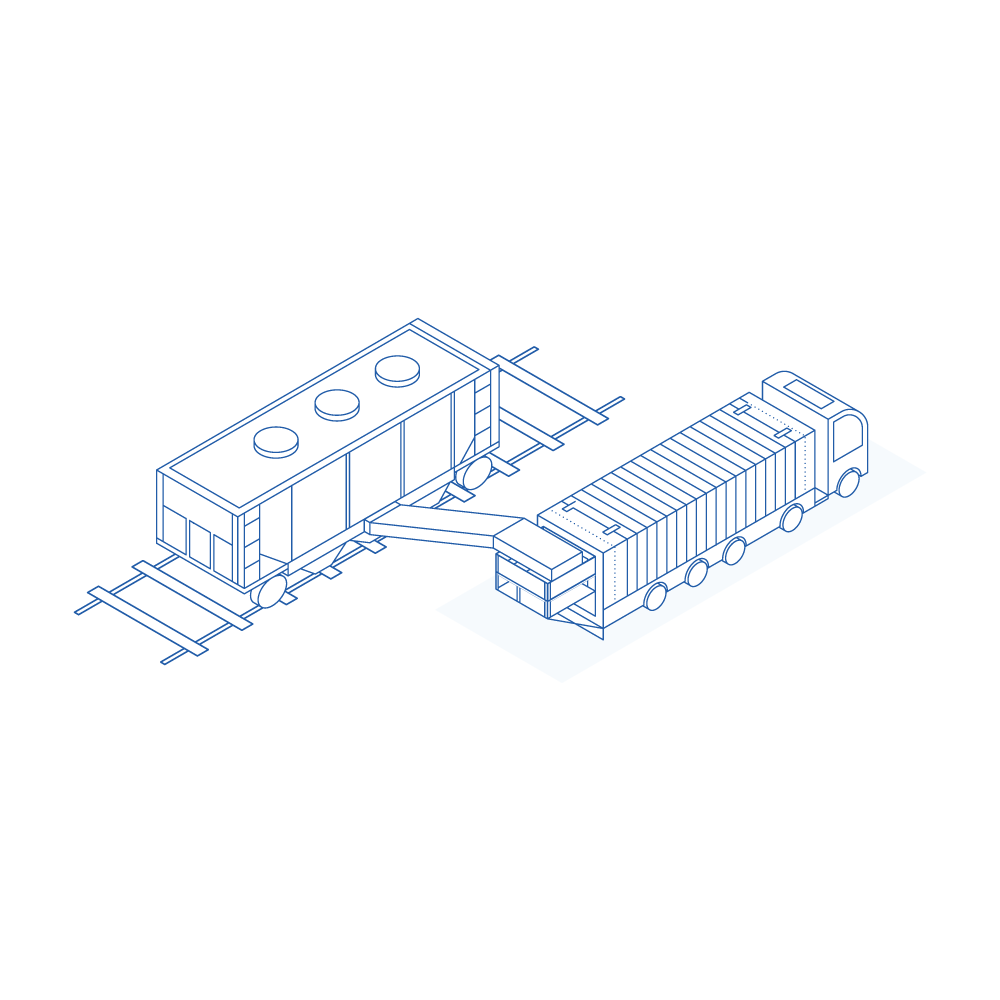

RB has the technology and the know-how to take care of multiple material handling solutions. We are specialized in transloading dry bulk materials from covered hoppers or pressure differential cars (PD Railcars) into different portable configurations, such as Sea Bulk Containers (SBC), pneumatic dry bulk tankers, amongst others.

From Railcar

Inspire the next, Extend your possibilities.

- From Railcar Into ISO Box Container

- From Railcar Into Dry Bulk Tanker

- From Railcar Into FIBC

- Particle size, shape and distribution

- Tamped, bulk and specific particle density

- Flowability

- Cohesive properties

- Friability and abrasiveness

- Fluidizability

- Hygroscopicity

Mechanical

PNEUMATIC

LEARN MORE ABOUT OUR POSSIBILITIES

RB offers customized solutions for every single project. According to the transload configuration, material and specific requests from our customers, we are able to design the system that suits best to each application. Furthermore, our trained and skilled personnel perform bulk handling operations worldwide daily, so we can provide complete services to cover all the transload needs of the supply chain.