Global Containerized Transport

Services / Transport /

Global Containerized Transport

CONNECTING BEYOND THE BORDERS

In 1966, the first transcontinental containerized shipment was performed from the United States of America to the Netherlands. Since then, the container transport industry has been at the center of an incredible expansion in international trade, which today touches all our lives in ways we cannot imagine.

The possibility to enter in new markets, the price pressure and the commoditization of many products has forced the industry to redesign their Supply Chain network. Through global sourcing, the organizations are continuously searching for emerging technologies to increase competitive advantage, add value to the customer and reduce costs.

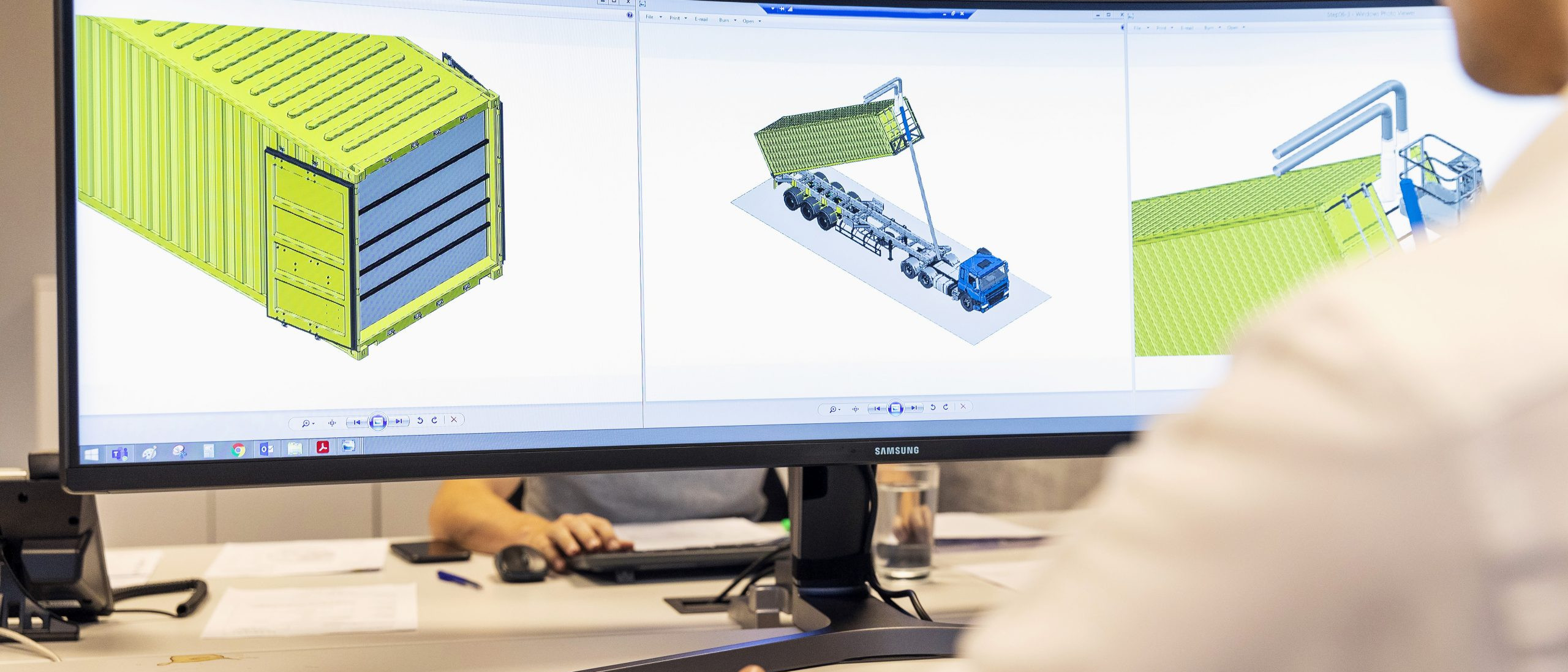

At RB, we are persistently working on innovation, improving our logistics solutions and using state of the art technology to address a cost efficient response to our customers demand.

We are specialized in door-to-door container-based logistics for the international bulk distribution of powdered and granulated materials.

DOOR TO DOOR, BULK TO BULK

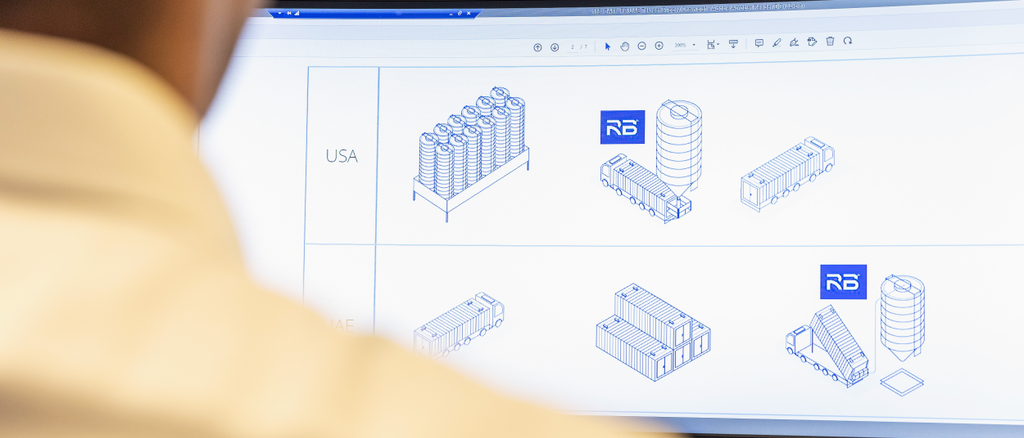

Our full container load (FCL) and Sea Bulk Container (SBC) services involve shipping a full container as a single unit. We can cover the complete transcontinental distribution process, from the bulk loading at origin until the bulk unloading at the final destination, including everything in between.

Through a methodological process, a coordinated team examines every single project meticulously, from the analysis of the material and its behavior under static and dynamic conditions, to all relevant details to be taken into account at the (un)loading site (flow rates, structural limitations, etc.).

At RB, we are aware of the importance of managing accurately every single variable present in the global supply chain to satisfy customers goals (lead times, cargo weight, vehicle sizes, legal requirements, personnel training, time difference, language and culture, amongst others).

Our full container load (FCL) and Sea Bulk Container (SBC) services involve shipping a full container as a single unit. We can cover the complete transcontinental distribution process, from the bulk loading at origin until the bulk unloading at the final destination, including everything in between.

Through a methodological process, a coordinated team examines every single project meticulously, from the analysis of the material and its behavior under static and dynamic conditions, to all relevant details to be taken into account at the (un)loading site (flow rates, structural limitations, etc.).

At RB, we are aware of the importance of managing accurately every single variable present in the global supply chain to satisfy customers goals (lead times, cargo weight, vehicle sizes, legal requirements, personnel training, time difference, language and culture, amongst others).

We have gained the confidence of World-Class customers by showing them our outstanding performance through the years. These are some of the proven benefits and value creation RB offers in the International distribution of Powder Products:

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

INCREASE PAYLOAD PER SHIPMENT

- Optimize the internal volume of the ISO Box Container, loading the inner liner with your dry bulk material instead of losing space by loading it with FIBCs and pallets.

- Freight savings.

- Eliminate the treated pallets from this supply chain process.

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

HUMAN EFFORT OPTIMIZATION

- No need to dedicate resources in repacking your product in FIBCs and moving pallets inside your production site. Why pack your goods when your end-customer wants to receive the material in bulk mode? Allocate the human resources to more valuable activities.

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

GAIN SPACE INSIDE THE PLANT

- Avoid holding space for unnecessary inventory of packed

product. - Generally, a silo occupies less than 30% of likewise space

for storing bags in multiple layers.

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

LESS INVENTORY OF PACKAGING AND PALLETS

- No need to buy and dedicate time and resources to control

the supply of pallets and bags.

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

STREAMLINE PRODUCTION

- Produce against stock replenishment, making the production more continuous and efficient. RB offers temporary and flexible storage possibilities in strategic locations s a buffer to balance the forces between supply and demand.

1. REDUCTION OF COST AND OPPORTUNITY SAVINGS:

REDUCTION IN CAPITAL INVESTMENT

- Subcontracting RB services allows reduction in possible capital investment. Customers can have preferences in allocating cash flow resources in other priority projects and core activities.

2. GAIN IN SAFETY AND SUSTAINABILITY:

2. GAIN IN SAFETY AND SUSTAINABILITY:

2. GAIN IN SAFETY AND SUSTAINABILITY:

3. FLEXIBILITY ADVANTAGES:

4. LEVEL OF SERVICE IMPROVEMENT:

5. PROCESS & CONTROL SIMPLIFICATION:

EXPLORE MORE

Thanks to our knowledge and expertise, we have been successful in developing innovative logistics solutions, but also in implementing them in the daily business on several continents.

Our goal is to truly understand the specific needs within your supply chain strategy and provide a solution to improve and secure the continuous and uninterrupted supply of goods. Find more about us here: