From Dry Bulk Tanker

Services / Transload /

From Dry Bulk Tanker

OUR EXPERIENCE, YOUR ADVANTAGE

RB applies all technology and expertise to offer efficient material handling services to support the competitiveness of our customers.

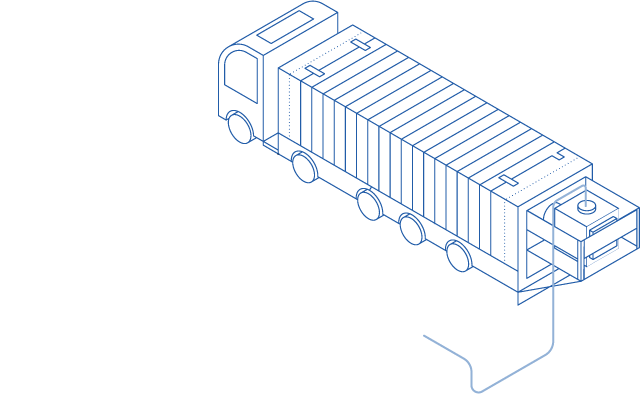

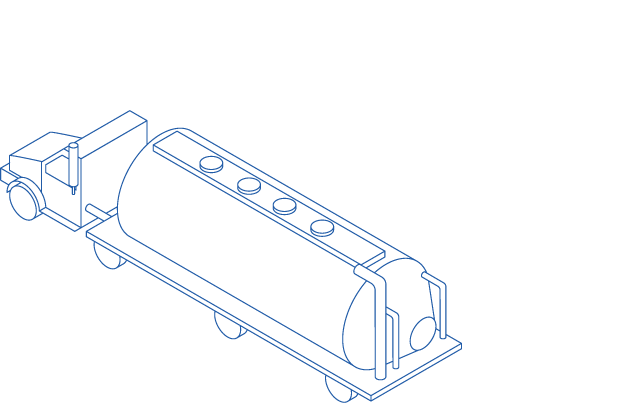

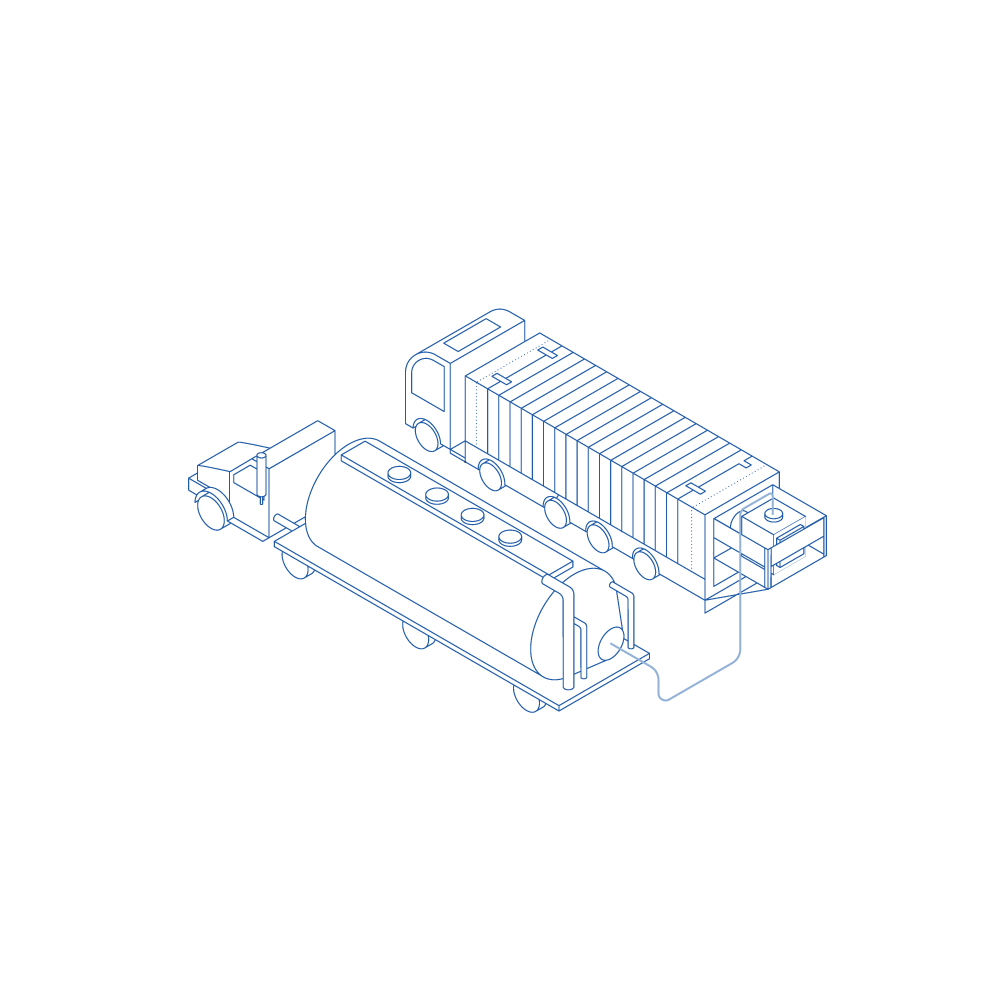

One of our most recurrent handling solution involves the possibility to transload powdered and granulated materials from Pneumatic Dry Bulk Tankers into different storage sources.

RB works on keeping the quality of the material through any transloading service, providing excellent results to our customers. Thus, we take care to adjust the operation to handle it gently and always being careful of its limitations:

- The compressed air, which is generated by a compressor placed on the transport unit, is constantly regulated to ensure it is used under safe values for the particles. Our units can work carefully under a maximum adjusted pressure of 2 Bar (29 PSI), being capable to handle a very wide range of bulk solid materials.

- We integrate a powerful intercooler to cool the air down before getting in contact with the product, preventing it could experiment excessive temperatures.

- In order to keep the material free of contamination, a filter is also used at this point to clean the air from water, oil or any other external particles.

Our units also have a pneumatic vibration system integrated at the outlet hopper to improve the unloading operation of products that have a poor flowability, usually found in solids that tend to cake.

FROM DRY BULK TANKER

GO WHEREVER YOU WANT TO

The possibility to transload powdered and granulated materials into different storage and transport sources represents a central service to satisfy every buying preference.

The ease to perform transloading operations from these units leads to several possible configurations. The most demanded services are:

- From Dry Bulk Tanker Into Silo

- From Dry Bulk Tanker Into ISO Box Container

- From Dry Bulk Tanker Into Railcar

- From Dry Bulk Tanker Into FIBC

FOCUS ON QUALITY

RB is committed to provide safe solutions not only for the material that is being handled, but also for the personnel working at the surroundings and for the environment.

Consequently, our pressurized tankers and containers are equipped with safety equipment, such as a relief valve, which avoids that they could suffer an over-pressurization. We also integrate dust collecting systems as required, ensuring a clean air and safe working conditions.

At the outlet, we use a pneumatic conveying system to transport the bulk solid directly to the new storage or to an intermediate handling system (which can be either pneumatic or mechanical, as required).

RB is committed to provide safe solutions not only for the material that is being handled, but also for the personnel working at the surroundings and for the environment.

Consequently, our pressurized tankers and containers are equipped with safety equipment, such as a relief valve, which avoids that they could suffer an over-pressurization. We also integrate dust collecting systems as required, ensuring a clean air and safe working conditions.

At the outlet, we use a pneumatic conveying system to transport the bulk solid directly to the new storage or to an intermediate handling system (which can be either pneumatic or mechanical, as required).

A NEW PARTNER IS RISING

Our extensive know-how and expertise make us capable to provide complete solutions in order to cover all our customers need: Besides handling systems, we can also integrate additional equipment (filling stations, intermediate silos, etc.) and even processing steps (sieving, blending, etc.) as required. Moreover, we can supply full transload services worldwide by our highly qualified teams, which are performing handling operations every day.

RB’s main objective is to offer successful services and optimize results to improve the supply chain. We analyze each single project and design tailor-made solutions, taking into account the application, the solid properties and any further request.