Competences /

Material Handling

IMAGINE WHAT WE CAN DO

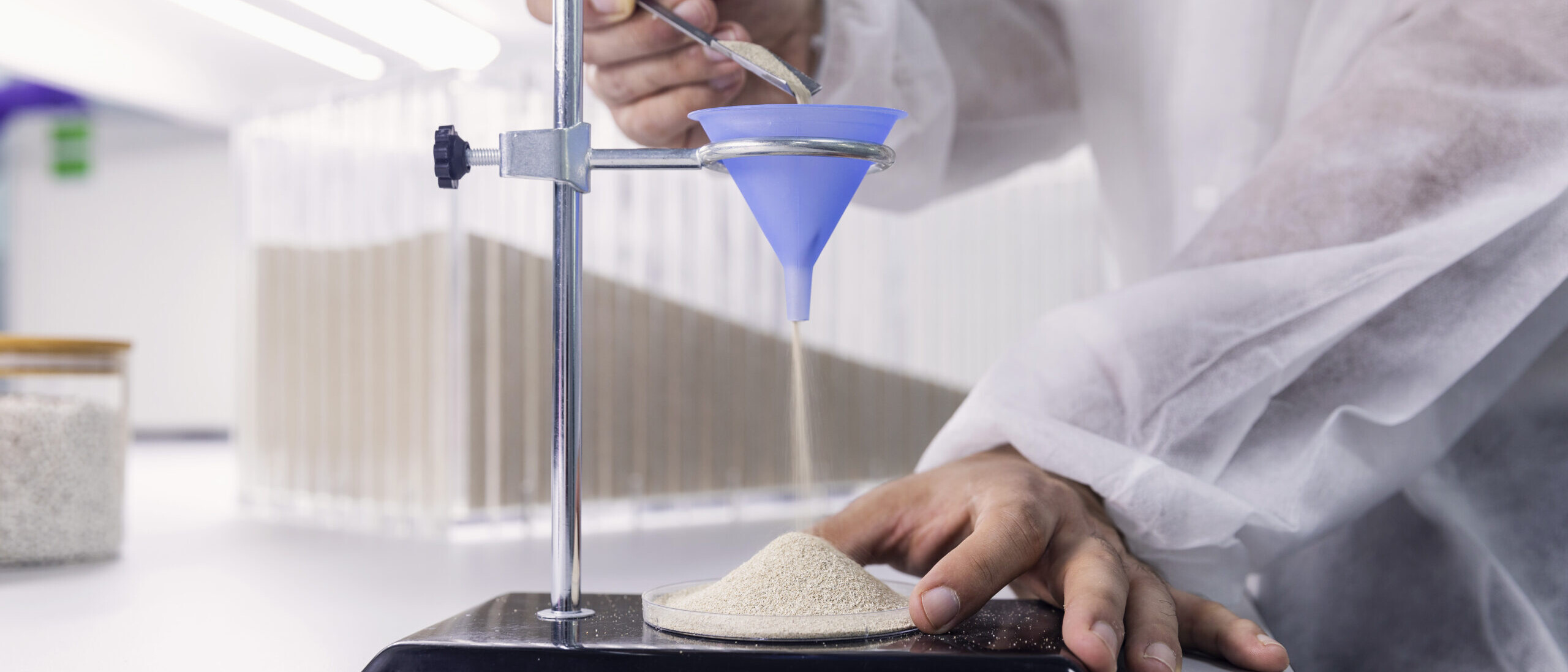

One of the most significant points in a supply chain is the handling procedure of the material. The success on this stage can provide tremendous benefits, such as reducing lead-time and maximizing the cost efficiency of the process. Nevertheless, the optimization of handling systems for powder and granular material can be challenging due to all the variables that must be taken into account.

The material itself is RB’s main object of study; it has a decisive role in the design of our equipment. Particle properties (size, shape, density…), flowability, abrasiveness, stickiness, caking behavior and handling hazards are a few material features that define the limitations and special considerations to determine the possible system configurations.

CONVEYORS

Machines that transport the material using the technology that suits better to the application.

- Mechanical type: Screws, belts, buckets, tube chains, among others.

- Pneumatic type: Pressure and vacuum technology (dilute or dense phase operation).

COMPONENTS

Equipment that links handling stages and/or performs an operation to the material.

- Loading/Unloading: Discharge and fill stations (sacks, FIBC and octabins), container lift systems, loading bellows, etc.

- Dosing: Rotary valves (drop or blow through type), diverters, gates, etc.

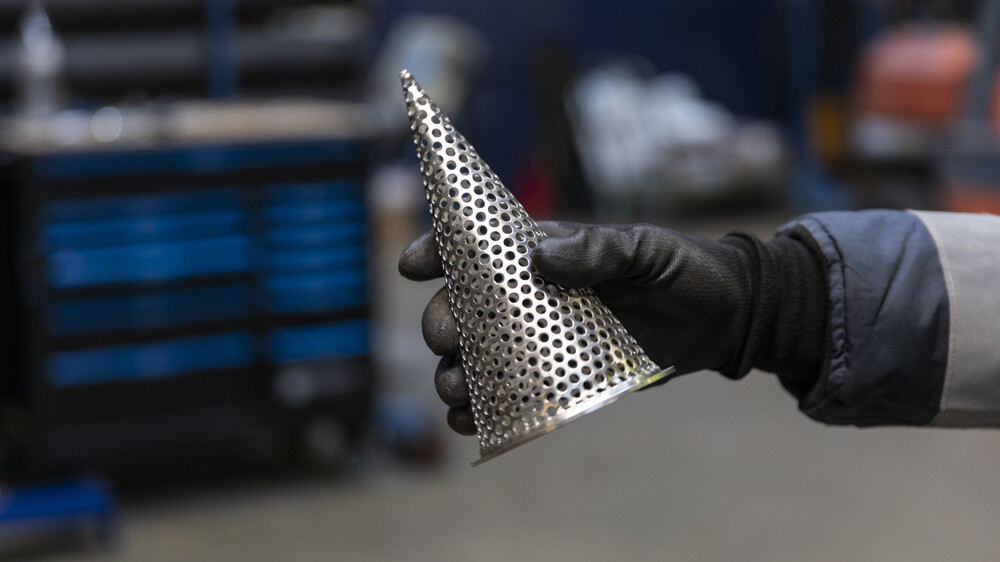

- Processing: Sievers, blenders, lump breakers, etc.

ACCESSORIES

Additional devices that complete the above mentioned parts in order to handle the material properly:

- Dust generating materials: Dust collecting systems and bag compactors.

- Hard-flow materials: Fluidizing systems, hammers, vibrators, etc.

RB analyses every single project thoroughly and gives tailor-made solutions, based on the material and customer’s requirements (facility limitations, local regulation, minimum flow rate, payload goal, etc.).

We study all the possible configurations in order to design an efficient solution that will achieve the targeted results, adjusting all the details of the system to the requested application.

For instance, we adapt every feature of the screw conveyors (such as the pitch & flight type, the trough, the hangers, etc.) in compliance with the specific handling conditions, or integrate a fluidizing system into the equipment that needs to generate a free-flow behavior of the material.

COMMITTED TO QUALITY

Keeping a high quality of the handled materials through the whole supply chain is also crucial. Any contamination can lead to multiple negative effects on the material: degradation of the particles, alteration in the chemical concentration, changes in the flow properties and flowability, among others. Likewise, material handling can have a reversed impact on the surroundings due to leakages or dust mismanagement.

A crossed contamination can cause not only economic repercussions, but also hazardous, environmental or reputational. In order to ensure a correct and safe operation, RB analyses the risks and adapts the solutions accordingly through the main features shown below:

- Hermetic equipment to seal and protect the handled material.

- Machines manufactured using specific materials and treatments to accomplish with handling requirements and reduce wear, such as stainless steel or hardened parts.

- Dedicated devices to work under ATEX and/or heavy-duty working conditions.

- Integration of dust collecting systems, which provide a dust free environment and protect against dust explosions.

Our knowledge and expertise offer numerous added values to our customers. We have already been successful in developing innovative handling solutions, but also in implementing them in the daily business on many continents.

The market is constantly evolving and can force the supply chain to upgrade the handling procedure in order to keep being competitive. Thanks to continuously working on improving our solutions and using state of the art technology, we are capable to provide specific handling options and integrate up-to-date equipment into a system that is already working and has specific demands.